Why the LM2500 Gas Turbine Demands Precision Aviation Parts

When it comes to performance, reliability, and versatility, the LM2500 gas turbine remains one of the most trusted power sources in aviation and industrial applications alike. Originally derived from GE's CF6 aircraft engine platform, the LM2500 has evolved into a workhorse for both aircraft engines and marine propulsion systems, powering everything from naval vessels to gas compressor stations and onboard aircraft power systems.

However, the same qualities that make the LM2500 engine so valuable—its high thermal output, compact modular structure, and operational flexibility—also make it incredibly demanding when it comes to maintenance and spare part compatibility. The stakes are high: even minor issues with aero aviation parts like airflow seal rings, nozzle guide vanes, or turbine blades can quickly escalate into system-wide inefficiencies or costly unplanned downtime.

That's where certified, precision-engineered aviation aftermarket parts come in.

In high-pressure environments such as those found within the LM2500, quality is non-negotiable. Operators need replacement parts that not only fit perfectly, but also perform reliably under extreme conditions. This is especially true for internal rotating parts and hot-section components, which must resist corrosion, thermal fatigue, and mechanical stress—all while maintaining tight clearances and thermal balance.

Whether you manage a fleet of turbine-powered aircraft or oversee maintenance for industrial-grade LM2500 installations, sourcing the right parts from experienced aviation parts companies is not just a technical choice—it’s a strategic advantage.

In this article, we’ll explore:

The structure and operational dynamics of the LM2500 gas turbine

High-demand LM2500 components in the aftermarket

Common procurement challenges for MROs and asset managers

How Liyan International provides a reliable solution for aviation parts supply

And why certified aviation parts for sale offer a better return on investment

Let’s begin by understanding what makes the LM2500 engine such a unique—and high-stakes—platform for critical aero components.

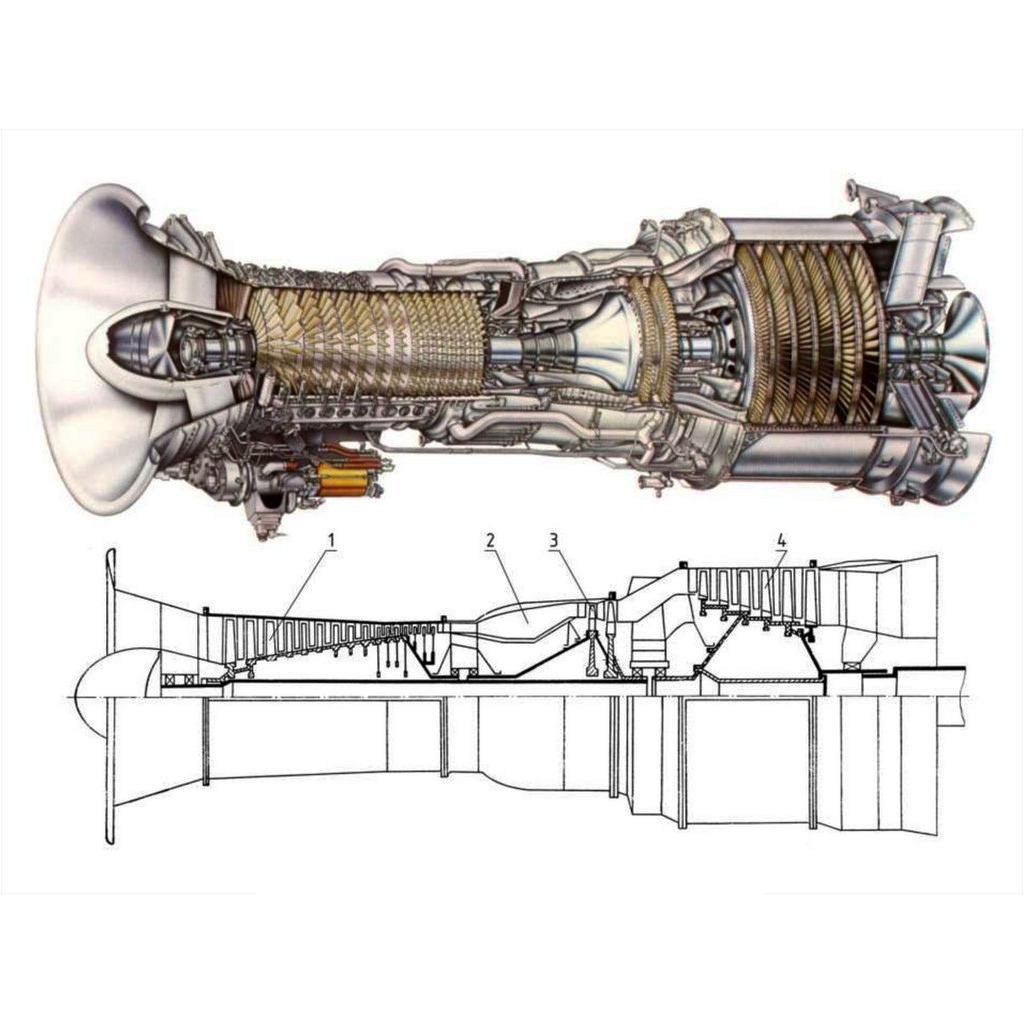

Understanding the LM2500 Gas Turbine: A Powerhouse Built on Proven Aircraft Engineering

The LM2500 gas turbine is a prime example of how aviation aircraft technology can be successfully adapted for marine and industrial use. Derived from GE’s CF6 turbofan engine, the LM2500 carries with it the heritage of aviation-grade performance—offering high power density, fuel flexibility, and proven reliability.

This turbine features a two-shaft configuration with a gas generator and a free power turbine. It includes:

A 16-stage axial-flow compressor

An annular combustor

A two-stage high-pressure turbine

A six-stage power turbine (in the LM2500+ and LM2500+G4 variants)

Each section of the LM2500 depends on aero aviation parts that are not only high-temperature resistant but also engineered to operate under extreme rotational speeds. This includes everything from turbine blades and vanes to outer and inner seal rings, support housings, and compressor casings.

Over 2,500 LM2500 units have been deployed globally, serving in aircraft carriers, LNG ships, gas compression stations, and military aircraft systems. However, such widespread use also means that maintenance cycles are intense and frequent. Parts wear down, tolerances shift, and seal integrity degrades under thermal cycling and vibration. As a result, MRO operators and parts buyers must plan for proactive replacements.

This is where the aviation aftermarket parts market becomes essential—especially when OEM lead times are long, and fleet readiness cannot be compromised.

In the next section, we’ll highlight the most in-demand parts and why sourcing them from certified aviation parts suppliers like Liyan International offers clear advantages.

High-Demand Aero Aviation Parts for LM2500 Maintenance

Whether powering a naval vessel or an energy facility, the LM2500 gas turbine operates under extreme stress—both thermal and mechanical. Over time, even the most durable components wear down. That’s why maintenance teams frequently look for high-performance aero aviation parts tailored for LM2500 applications.

Commonly Replaced Aviation Aftermarket Parts for LM2500:

Turbine Nozzle Guide Vanes – Exposed to continuous hot gas flow, these parts suffer from erosion and oxidation.

Outer and Inner Airflow Seal Rings – Maintain crucial pressure balance and prevent air leakage between turbine stages.

Combustor Liners – Withstand high heat and require coatings to manage thermal fatigue.

Bearing Housings and Support Assemblies – Ensure proper shaft alignment and reduce vibration.

High-Pressure Turbine Blades – Among the most stressed parts, subject to creep and corrosion.

These components must meet precise specifications. Any deviation—even a fraction of a millimeter—can impact the turbine’s balance, increase vibration, and lower operational efficiency. That’s why experienced engineers and procurement specialists increasingly turn to aviation parts suppliers who offer certified aviation aftermarket parts rather than risking unverified alternatives.

Moreover, unlike generic gas turbines, the LM2500 relies on aero-grade metallurgy, coatings, and CNC-machined geometry for peak performance. That makes it essential to partner with aviation parts companies who understand both turbine dynamics and aviation engineering tolerances.

In the following section, we’ll explain how sourcing from trusted aviation parts supply companies like Liyan International helps reduce risk, minimize downtime, and extend the lifecycle of your LM2500 engine.

Why Sourcing from Certified Aviation Parts Suppliers Matters

In high-stakes environments like naval propulsion and industrial energy generation, every component in your LM2500 turbine counts. Using the wrong part—or even the right part from the wrong supplier—can lead to severe consequences: unplanned outages, inspection failures, or costly overhauls. This is why sourcing aviation aftermarket parts from certified aviation parts suppliers is not just a preference—it’s a requirement.

Risks of Non-Certified Components

Some procurement teams, under pressure to cut costs or meet tight deadlines, consider off-brand or non-traceable aviation parts for sale. While the upfront savings might look attractive, these decisions often backfire. Common problems include:

Dimensional inaccuracies that cause alignment or sealing issues.

Material inconsistencies leading to early fatigue or corrosion.

Lack of compliance documentation, making it impossible to pass regulatory or customer audits.

Poor customer support, which delays installation and causes operational bottlenecks.

Each of these issues results in lost productivity, safety concerns, and increased long-term costs. For mission-critical operations relying on the LM2500 gas turbine, there’s no room for compromise.

What Certified Aviation Parts Companies Deliver

At Liyan International, we solve these pain points by offering:

✅ Traceable, OEM-compatible parts – Each part comes with full documentation including MTRs, heat treatment records, and inspection reports.

✅ AS9100-certified quality management – Our production process ensures consistency and compliance across every unit.

✅ Expert reverse engineering – Even if original drawings are lost, we can rebuild and certify replacements using worn components or sketches.

✅ Supportive logistics – We help with HS codes, export declarations, and customs procedures for fast, compliant delivery.

By choosing a trusted aviation parts supplier, you not only get the parts you need—you get confidence in your turbine’s long-term performance.

Liyan International’s Precision-Engineered LM2500 Parts

When it comes to aero aviation parts for LM2500 gas turbines, Liyan International delivers more than just replacements—we deliver performance, safety, and peace of mind.

Built for Harsh Operating Conditions

The LM2500 gas turbine operates under intense thermal loads, high-velocity airflow, and vibration-prone environments. Whether it's powering a naval vessel or a land-based power plant, this engine demands parts that meet the same rigorous standards as OEM components. That’s where Liyan excels.

We provide aviation aftermarket parts that are:

CNC-machined to micron-level tolerances, ensuring perfect fit and minimal vibration.

Made from aerospace-grade alloys, including high-temperature steels and superalloys like Inconel.

Heat-treated and coated to resist oxidation, wear, and corrosion even in saltwater or desert climates.

Delivered with full traceability, including batch codes, heat treatment logs, and mechanical property test results.

Parts We Commonly Supply for the LM2500

Here are some of the most requested LM2500 components in our aerospace inventory:

Combustion liner assemblies

Turbine nozzle guide vanes

Bearing support housings

Seal rings and airflow baffles

Fuel nozzles and atomizers

Hot section components, such as turbine shrouds and stator vanes

Control system sensor ports and mounts

All components are fully compatible with GE LM2500 and LM2500+ models and can be delivered globally, with or without ITAR restrictions depending on region and use.

Flexible Support for Any Customer Type

Whether you're a naval maintenance officer, power station procurement lead, or third-party MRO provider, Liyan offers customized solutions:

Low minimum order quantities for repair shops and urgent AOG replacements

Volume pricing for fleet operators or scheduled maintenance programs

Reverse engineering and prototyping for discontinued or legacy components

End-to-end export support, including export licenses when required

We don't just ship parts—we work alongside your team to make sure every product fits your schedule, system, and quality expectations.

Trusted by Operators Worldwide: Proven Applications of LM2500 Parts

When it comes to global trust and field-proven reliability, few engines have the legacy of the LM2500 gas turbine. Likewise, few suppliers offer the versatility and support that Liyan International delivers across multiple industries and regions.

Across Industries and Continents

The LM2500 is a true cross-sector powerhouse. Originally derived from aviation, it now powers everything from frigates and destroyers to offshore oil platforms and remote energy facilities. As such, our aero aviation parts serve a wide range of professional end-users:

| Customer Type | Common Use Case |

|---|

| Naval Forces | Hot section parts for marine propulsion upgrades |

| Power Generation Plants | Combustion components for peaker and base load stations |

| Offshore Oil & Gas | Sealing systems and hardware for floating installations |

| Turbine Overhaul Shops | Certified replacements for modular rebuild programs |

| Government Contractors | Retrofit kits for defense-specific LM2500 configurations |

Each customer faces unique challenges, but they all share the same priorities: safety, compliance, performance, and fast turnaround.Maintenance-Critical Parts

Due to the high-output nature of the engine, certain components see accelerated wear and must be replaced or inspected regularly. These include:

We maintain rotating inventory for many of these parts, ensuring that your procurement lead time is minimized—often reduced to just a few days depending on region and logistics.

Your Operations Can’t Afford Downtime

Unplanned maintenance on an LM2500 gas turbine can lead to:

Lost megawatts of output in power plants

Missed mission windows for naval vessels

Increased wear on adjacent components

Penalties from regulatory bodies if documentation is lacking

That’s why Liyan emphasizes both the performance of our parts and the efficiency of our delivery process. We ship globally with full customs support and documentation—including ITAR, ECCN, or NATO-compliant paperwork when necessary.

Why Certified Parts Matter for LM2500 Gas Turbine Maintenance

In the high-stakes world of turbine operations—whether at sea or on land—certified parts aren’t a luxury. They’re a necessity. Your LM2500 gas turbine must run under extreme pressure, temperature, and vibration conditions. Every component—especially sealing rings, nozzles, and hardware—plays a critical role in maintaining performance and preventing catastrophic failure.

Safety, Compliance, and Audit Readiness

Operators today face increasing scrutiny from regulatory agencies. Whether you answer to ISO, AS9100, FAA, EASA, or military procurement officers, your parts must:

Be traceable to certified sources

Include full dimensional and material test reports (MTRs)

Comply with inspection and quality control documentation standards

Be ready for random or scheduled audits

At Liyan International, every part—especially aftermarket components like the outer rotating seal rings for LM2500—comes with full traceability, batch documentation, and quality certifications.

We don't just help you install the part. We help you pass the audit.

Longer Lifespan = Lower Total Cost

Certified aero aviation parts deliver more than safety. They deliver economic value.

Poor-quality parts might save you money up front—but they often:

Wear out prematurely

Require earlier replacement

Create alignment and vibration issues

Fail to pass quality audits

In contrast, our components are CNC-machined from aerospace-grade materials like Inconel and Hastelloy, engineered for high-velocity airflows, combustion zones, and rotating interfaces. This precision translates to longer maintenance intervals, lower downtime, and fewer emergency repairs.

It’s Not Just About Price—It’s About Peace of Mind

Fleet managers and turbine engineers increasingly understand that the lowest price doesn't mean the best deal. Instead, success lies in sourcing proven, well-supported, and compliant parts from a partner who understands your operational demands.

That’s why industry professionals across general aviation, marine power, and industrial energy continue to choose Liyan. Because the true cost of turbine maintenance includes:

The part

The paperwork

The delay

The risk

With Liyan, all four are under control.

Ready to Upgrade Your LM2500 Turbine Parts Supply?

Whether you're managing marine propulsion systems, offshore platforms, or land-based power generation, one truth remains clear—your LM2500 gas turbine deserves better parts. At Liyan International, we help you take control of your maintenance schedule, reduce procurement headaches, and keep your turbines operating at peak performance.

We supply:

✅ CNC-machined aero aviation parts engineered for LM2500 turbines

✅ Fully certified components, including seal rings, nozzles, and support hardware

✅ Fast global delivery with export paperwork and HS code prep

✅ Technical consultation for hard-to-identify or obsolete part replacements

✅ Competitive bulk pricing for aviation aftermarket parts

From aviation parts supply to reverse-engineered solutions, we support your team with precision, speed, and industry-grade compliance.

Contact Liyan International today for a free quote, datasheet, or technical review. We typically respond within 24 hours—with real solutions, not generic replies.