The CFM56-7B engine components are precision-engineered parts developed exclusively for the Boeing 737 Next Generation (NG) series, including the 737-600, 737-700, 737-800, and 737-900 models. As part of the industry-leading CFM56-7B engine, these components—such as fan blades, high-pressure turbine blades, combustion chambers, engine casings, and bearing supports—ensure exceptional performance, reliability, and fuel efficiency. Manufactured by CFM International, a joint venture between GE Aviation and Safran Aircraft Engines, these parts meet the highest aviation standards, making them a trusted choice for airlines worldwide.

The CFM56-7 engine, developed by CFM International, is the exclusive engine for the Boeing 737 Next Generation (NG) series, which includes the 737-600, 737-700, 737-800, and 737-900. With millions of flight hours logged, the CFM56-7 engine parts have proven to be reliable, efficient, and industry-leading in performance. Let’s delve into the features of these components and why they are vital for modern aviation.

The CFM56-7 engine was designed specifically to meet the needs of the 737 NG series, offering exceptional performance for short- to medium-haul flights. Here are its standout features:

The CFM56-7 engine balances performance and efficiency, making it ideal for narrow-body aircraft like the Boeing 737 NG. Its design ensures consistent power delivery with reduced fuel consumption.

Engineers use CFM materials that withstand high temperatures and stress, ensuring the engine delivers reliable performance under demanding conditions.

The engine features enhanced durability, with longer intervals between overhauls. This reduces maintenance costs for airlines and increases operational efficiency.

The CFM56-7 and CFM56-7B engines belong to the same family of the CFM56 series. However, the CFM56-7B is an upgraded and optimized version of the CFM56-7, designed to meet modern aviation requirements. Below is an explanation of their relationship and key differences.

Development and Purpose:

The CFM56-7 was developed by CFM International specifically for the Boeing 737 Next Generation (NG) series.

It is a part of the broader CFM56 engine family, providing efficient and reliable power for single-aisle aircraft.

Applications: It powers the Boeing 737-600, 737-700, 737-800, and 737-900 models.

Technical Features:

High aerodynamic efficiency.

Designed to meet the fuel efficiency and reliability demands of the time.

Upgrades and Optimizations:

The CFM56-7B is an enhanced version of the CFM56-7, incorporating advancements to improve performance.

It addresses the growing demands for better fuel efficiency, lower emissions, and simplified maintenance.

Key Features:

Higher Fuel Efficiency: Enhanced combustion technology reduces fuel consumption.

Lower Emissions and Noise Levels: Meets stricter environmental and noise regulations.

Greater Thrust Range: Offers thrust from 19,500 lbs to 27,300 lbs, accommodating various Boeing 737 NG configurations.

Wide Usage:

The CFM56-7B became the standard engine for the Boeing 737 NG series and forms the technological foundation for the newer Boeing 737 MAX series.

| Feature | CFM56-7 | CFM56-7B |

|---|---|---|

| Thrust Range | 18,500–23,500 lbs | 19,500–27,300 lbs |

| Fuel Efficiency | Standard fuel efficiency | Improved by ~3% |

| Noise and Emissions | Meets older standards | Complies with stricter modern standards |

| Maintenance Cycle | Standard intervals | Longer intervals, reduced cost |

| Applications | Boeing 737 NG series | Boeing 737 NG series (optimized) |

The CFM56-7B is a refined version of the CFM56-7, offering enhanced fuel efficiency, lower operating costs, and compliance with stricter environmental standards. As the aviation industry evolves, the CFM56-7B has become the mainstay engine for the Boeing 737 NG series, providing airlines with a more efficient and reliable powerplant for their fleets.

The CFM56-7B engine, developed by CFM International—a joint venture between GE Aviation and Safran Aircraft Engines—is the exclusive powerplant for the Boeing 737 Next Generation (NG) series. Known for its reliability, efficiency, and durability, the CFM56-7B powers the 737-600, 737-700, 737-800, and 737-900, making it an industry leader in the single-aisle aircraft market.

The CFM56-7B is engineered to meet the unique demands of the Boeing 737 NG series. It stands out for its advanced technology and innovative design, ensuring optimal performance for short- and medium-haul flights.

The CFM56-7B delivers excellent fuel efficiency, helping airlines reduce operating costs. Its design optimizes airflow and combustion, ensuring maximum thrust with minimal fuel consumption.

With millions of flight hours logged, the CFM56-7B is one of the most reliable engines in aviation history. Its durable construction and advanced materials ensure consistent performance under demanding conditions.

The engine meets stringent noise and emission standards, aligning with global efforts to reduce aviation’s environmental impact. Noise reduction kits and advanced combustion chambers help airlines stay compliant.

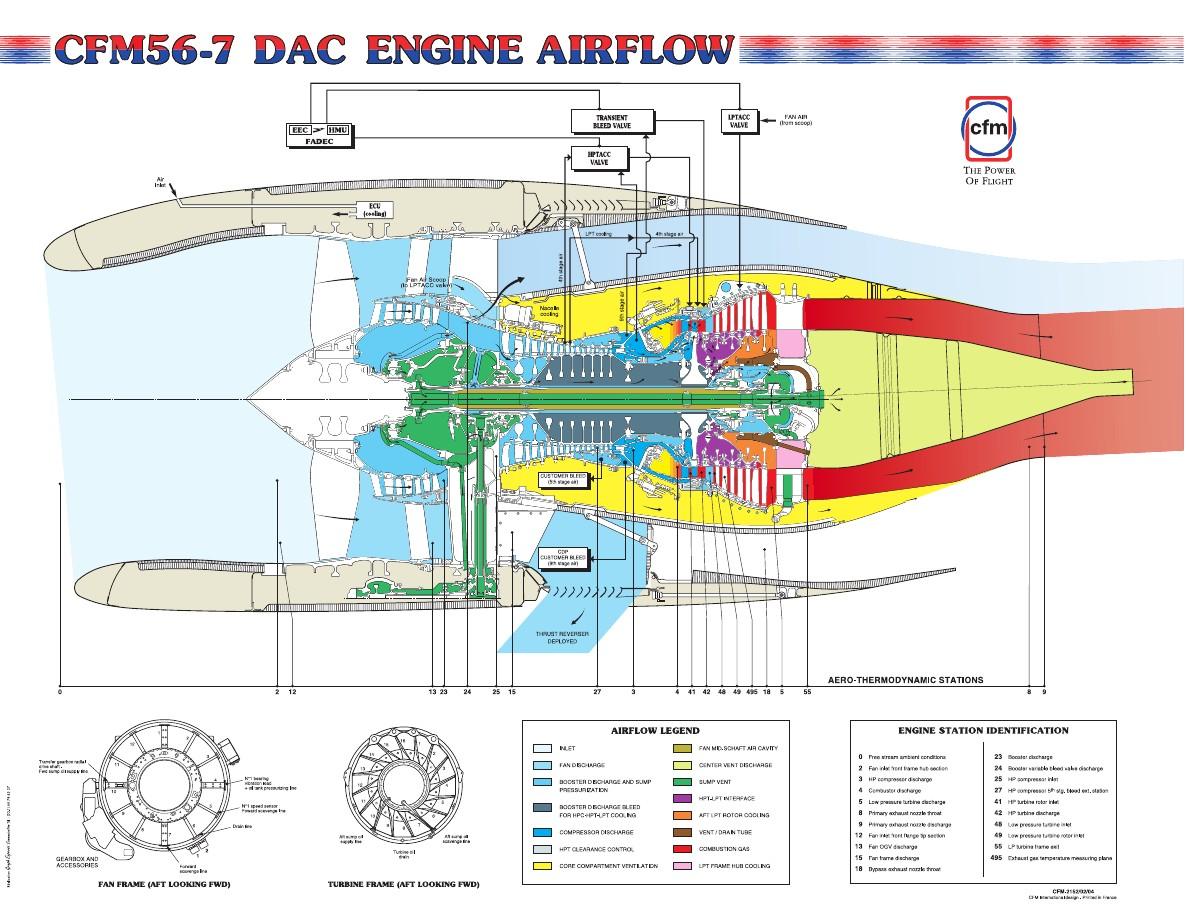

The CFM56-7B engine consists of numerous precision-engineered parts, each playing a vital role in its operation. Here’s a closer look at the key CFM56-7B components:

Function: Drive airflow into the engine.

Importance: Enhance thrust and reduce noise, ensuring compliance with modern regulations.

Function: Mix fuel and air for ignition to generate thrust.

Importance: Ensure efficient and clean combustion, reducing fuel consumption and emissions.

Function: Convert energy from hot gases into mechanical power.

Importance: Improve efficiency and extend the engine’s life.

Function: Protect internal components and maintain structural integrity.

Importance: Minimize the risk of mechanical failures while maintaining engine stability.

Function: Stabilize moving parts and reduce friction.

Importance: Enhance operational efficiency and prolong component life by minimizing wear.

Function: Connect and stabilize fan blades.

Importance: Ensure aerodynamic balance for optimal airflow and performance.

High-quality CFM56 engine parts are essential for maintaining performance and safety. Airlines operating the Boeing 737 NG series rely on these components for several reasons:

Efficiency: Precision-engineered parts ensure optimal fuel consumption, reducing operating costs.

Durability: Advanced materials and innovative designs withstand extreme conditions, ensuring longer intervals between maintenance.

Safety: Reliable components minimize the risk of mechanical failure, providing peace of mind for airlines and passengers alike.

The CFM56-7B engine remains a popular choice for operators due to its robust design and availability of upgrade options. Here are some common maintenance and enhancement solutions:

These kits reduce engine noise, ensuring compliance with stringent noise regulations while improving passenger comfort.

Advanced combustion technologies improve fuel economy, helping airlines cut costs and reduce emissions.

Replacing critical parts, such as turbine blades and combustion chambers, ensures the engine continues to deliver reliable performance over its operational life.

CFM International is a global leader in aviation, renowned for its cutting-edge technology and commitment to quality. Here’s why the company stands out:

As a joint venture between GE Aviation and Safran Aircraft Engines, CFM International combines the expertise of two aerospace giants to deliver world-class engines.

With over 33,000 engines produced, the CFM56 series is trusted by airlines worldwide for its dependability and performance.

Operators benefit from CFM International’s extensive maintenance and support network, ensuring they can access high-quality parts and services wherever needed.

The CFM56-7B engine has been instrumental in the success of the Boeing 737 NG series. Its unmatched efficiency, durability, and environmental performance make it the preferred choice for single-aisle aircraft. Airlines continue to rely on the CFM56-7B for its proven ability to meet the demands of high-utilization fleets.

The CFM56-7 engine comprises precision-engineered parts, each playing a critical role in ensuring safety, efficiency, and reliability. Below are the most important components:

Function: Direct airflow into the engine.

Importance: Improve thrust while minimizing noise, critical for passenger comfort and compliance with environmental standards.

Function: Convert hot gas energy into mechanical power.

Importance: Enhance fuel efficiency and extend the engine’s lifespan.

Function: Mix and ignite fuel and air to generate thrust.

Importance: Ensure efficient combustion, reducing fuel consumption and emissions.

Function: Provide structural support and protect internal components.

Importance: Maintain engine stability and minimize mechanical failures.

Function: Stabilize moving parts and reduce friction.

Importance: Prolong operational life by minimizing wear and tear.

For an aircraft like the Boeing 737 NG, which is known for its high utilization rates, using top-quality CFM56 engine parts is essential. These components ensure:

Efficiency: Lower fuel consumption reduces operational costs.

Reliability: Durable materials withstand challenging flight conditions.

Safety: Precision-engineered parts minimize the risk of mechanical failure.

Maintaining these components in optimal condition is vital for maximizing uptime and extending the engine’s lifespan.

When sourcing CFM56-7B components, reliability and precision are critical. Liyan International Manufacturing Co., Ltd. specializes in producing high-precision components for the CFM56-7 engine, including fan blades, turbine components, and bearing supports. With advanced manufacturing techniques and strict quality standards, Liyan International ensures your fleet operates at peak efficiency.

The CFM56-7 engine, powering the Boeing 737-600/700/800/900, is a testament to the engineering excellence of CFM International. Its advanced materials, durable components, and innovative design make it a leader in the commercial jet engine market. Maintaining these engines with top-quality CFM56 parts ensures long-term efficiency, reliability, and safety.

Precision Manufacturing: State-of-the-art equipment ensures high-quality, reliable components.

Global Reputation: Trusted by leading airlines and operators worldwide.

Comprehensive Support: Dedicated customer service to help you find the right solutions for your fleet.

The CFM56-7B engine, powering the Boeing 737-600/700/800/900, is a testament to engineering excellence. Its advanced materials, innovative design, and durable components make it a leader in the commercial jet engine market. Maintaining these engines with top-tier CFM56-7B components ensures long-term efficiency, reliability, and safety.

For trusted CFM engine parts that meet the highest standards, choose Liyan International. Contact us today to learn more about how our products can support your fleet's operational success.

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat