Liyan International specializes in precision-manufactured GE90 jet engine components for long-range aircraft such as the Boeing 777. Our product line includes turbine sealing rings, bearing housings, intermediate supports, and nozzle flange rings, all CNC-machined from aerospace-grade alloys. With certifications including FAA, EASA, and AS9100, every part is fully traceable and engineered for high-performance aircraft maintenance and OEM integration. Trusted by MROs, leasing companies, and airlines worldwide, Liyan delivers superior aircraft engine parts that reduce cost per flight hour and improve operational safety.

Looking for a high-thrust, high-efficiency solution for wide-body aircraft? The GE90 jet engine from General Electric is a proven leader.

It has massive 115,000-pound maximum thrust on the GE90-115B variant. This engine powers some of the world's most capable long-haul aircraft, including the iconic Boeing 777.

It entered service with Air France in November 1995 and has since become a trusted asset in the fleets of British Airways, Emirates, and many others.

Its impressive combination of power, fuel efficiency, and durability has made it the go-to turbofan engine for operators seeking longer range and reduced maintenance costs.

From its composite fan blades to its modular design, the GE90 exemplifies the future of aviation engineering—even decades after its launch.

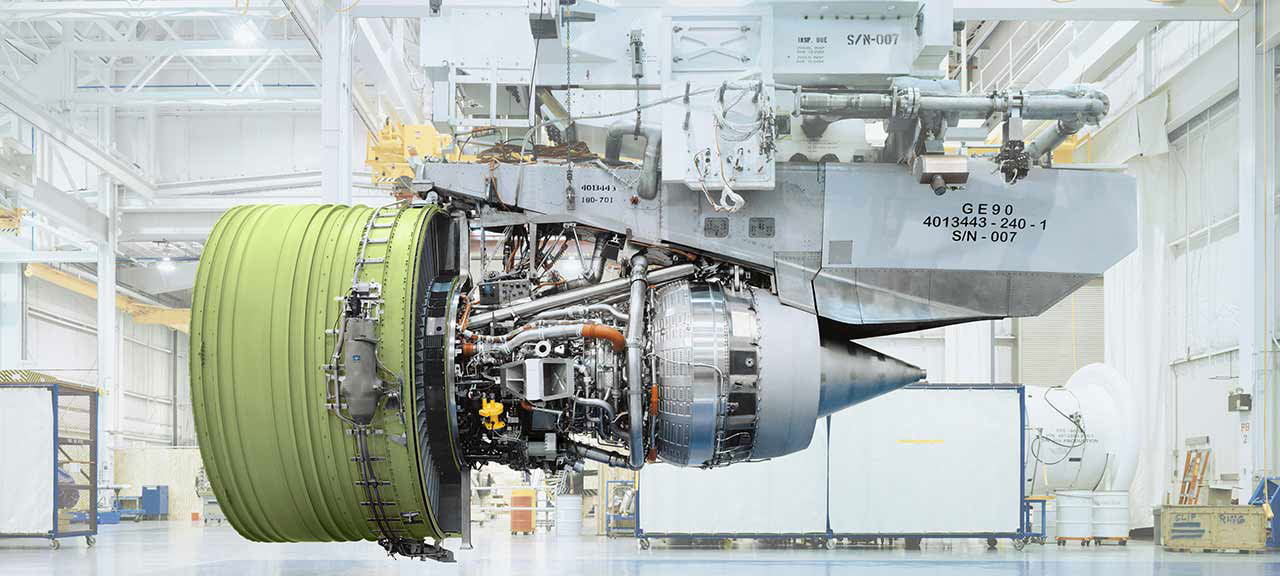

The General Electric GE90 isn’t just a larger engine—it’s smarter, lighter, and more powerful than its competitors. Designed as a twin-spool, high-bypass turbofan, the engine features several advanced technologies:

Fan System: With a diameter of 128 inches, the fan is one of the largest ever produced and uses lightweight carbon fiber composite blades for increased efficiency and reduced weight.

Low-Pressure Compressor (LPC) and High-Pressure Compressor (HPC): The 10-stage HPC delivers extremely high compression ratios, boosting combustion performance.

Combustor: The TAPS (Twin Annular Pre-Swirl) system reduces NOx emissions and promotes clean, efficient combustion.

High and Low-Pressure Turbines: These critical modules convert combustion energy into mechanical thrust. Their blades operate under extreme thermal and mechanical stress—requiring advanced materials and precise engineering.

Main Shaft Bearings and Seal Rings: These include components like the 576 TO GE and 438 TO GE, which ensure proper sealing, lubrication, and rotational stability.

With a bypass ratio of 9:1, the engine burns less fuel and emits fewer pollutants—an essential feature in today’s eco-conscious aviation landscape.

Engineers and maintenance managers value the GE90 for multiple reasons, many of which offer direct operational and financial benefits:

| Feature | Advantage |

|---|---|

| High Thrust Output | Handles long-haul routes and larger aircraft loads |

| Composite Fan Blades | Reduces engine weight and fuel consumption |

| TAPS Combustion Technology | Cuts emissions, meets global environmental standards |

| Health Monitoring System | Enables predictive maintenance and reduces unexpected failures |

| Modular Engine Design | Simplifies replacement and overhauls, reducing MRO downtime |

When you’re flying across continents, reliability isn't optional—it’s essential. And that’s exactly what the GE90 delivers.

As the engine of choice for powered Boeing 777 aircraft, the GE90 is widely used across the globe. However, high usage leads to wear—and that creates demand. Aircraft maintenance teams routinely require high-quality replacement parts to keep these engines airworthy and compliant with aviation safety standards.

Some of the most frequently replaced superior aircraft engine parts include:

Turbine Sealing Rings

Bearing Housing Assemblies

Combustor Nozzle Components

Intermediate Structural Supports (e.g., 1733 TO GE)

Nozzle Guide Vanes

Turbine Support Flange Rings (e.g., 124 TO GE)

Fan Bearing Support Assemblies

High/Low Pressure Turbine Blades

Many of these parts operate under extreme conditions. As a result, aircraft operators can’t afford low-quality alternatives. The stakes are too high. That's why superior aviation components with FAA/EASA certification are essential for any maintenance plan.

At Liyan International, we understand that your GE90 engine is a multimillion-dollar investment. Every component must perform with precision under intense thermal, mechanical, and operational stress. That’s why we manufacture and supply GE90 jet engine parts with uncompromising attention to detail.

From seal rings to turbine flange supports and bearing housings, every product we ship is:

CNC-machined to exact tolerances.

Constructed from aerospace-grade alloys (including high-nickel superalloys).

Delivered with FAA/EASA-compliant documentation.

Backed by a quality assurance process in accordance with AS9100 standards.

Unlike generic suppliers, we specialize in engine aircraft parts that are truly mission-critical. Our customers—ranging from aircraft engine parts distributors to MRO operations—rely on us for quality, consistency, and traceability.

Because the GE90 engine powers many long-haul aircraft, our parts serve a wide variety of customers in both civil and commercial aviation:

| Customer Type | Application |

|---|---|

| Major Airlines | Replace worn components during scheduled overhauls or A/B/C-checks |

| Aircraft Leasing Companies | Overhaul GE90 units prior to lease returns or redelivery |

| OEMs | Integrate FAA-compliant parts into new production or refurbishment modules |

| MRO Providers | Procure spare aircraft jet engine parts to fulfill third-party service contracts |

| Military & Defense Fleets | Apply replacement parts to fleet-sustaining heavy jet maintenance programs |

From British Airways to Air France, and from Asia-Pacific to South America, we’ve helped keep thousands of GE90 engines in the sky—operating safely, efficiently, and without disruption.

Sourcing from verified, engineering-based manufacturers like Liyan means:

Fewer installation errors due to tight tolerances and OEM-matched specs.

Better long-term performance, reducing the total cost per flight hour.

Shorter lead times, thanks to vertically integrated production and regional stock.

Easier audits, since every part is traceable, certified, and compliant.

In fact, many customers switch to Liyan not just for the savings—but because they’re tired of receiving unmarked parts, incomplete documents, or inconsistent supply. When managing aircraft engines, you deserve better. That’s why we focus on superior air parts that meet your expectations in both form and function.

Don’t risk your next overhaul with an unreliable source. Whether you need airplane engine parts for GE90-94B, GE90-115B engine support, or modular replacements for a mixed fleet—Liyan International is your strategic partner.

We provide:

✅ Full traceability with MTRs, dimensional reports, and heat treatment data

✅ End-to-end export support, including customs clearance and HS code classification

✅ Short-run prototyping for hard-to-find parts

✅ Volume pricing for aircraft engine parts for sale across MRO and OEM channels

Contact us now to request a free quote or technical consultation. We’ll respond within 24 hours and help you reduce downtime and inventory risk.

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat