Liyan International supplies high-quality components for the LEAP-1A, LEAP-1B, and LEAP-1C engines, including parts like front transition duct hangers, turbine front segment sealing rings, fan front supports, and bearing housings. These components are precision-engineered to enhance the performance, reliability, and efficiency of CFM LEAP engines, which power aircraft such as the Airbus A320neo and Boeing 737 MAX. Designed to meet the highest aviation standards, these parts contribute to reduced fuel consumption, longer flight hours, and lower CO2 emissions, supporting the industry's shift toward more sustainable aviation.

The LEAP engine, a revolutionary product produced by CFM International, has taken the aviation world by storm. The President and CEO of CFM International, Jean-Paul Ebanga, has been leading the company. Which is a joint venture between GE Aviation and Safran Aircraft Engines. Its mission is to develop and supply world-leading jet engines.

This state-of-the-art jet engine powers some of the most popular modern aircraft, including the Airbus A320neo and Boeing 737 MAX.

Remarkable fuel efficiency and eco-friendly design, the LEAP engine represents the next generation of aircraft engines. It improves airline operations, and reducing both fuel consumption and CO2 emissions.

The LEAP engine is not just another jet engine—it’s a breakthrough in aerospace technology. It utilizes cutting-edge materials and engineering designs. That makes it one of the most efficient engines in modern aviation.

The LEAP 1A engine aircraft is specifically the Airbus A320neo, while the LEAP-1B engine powers the Boeing 737 MAX.

Fuel Efficiency and Reduced Emissions:

The LEAP aircraft engine features an advanced design that reduces fuel consumption by 15% compared to older engines. It also reduces CO2 emissions by 16%. This makes it a smart choice for airlines that want to lower their carbon footprint.

High-Performance Turbine Blades:

One of the key innovations in the LEAP engine is its use of ceramic matrix composites (CMCs). These materials allow the turbine blades to withstand higher temperatures, leading to better fuel efficiency and overall engine performance.

Longer Flight Hours and Durability:

With its robust design, the LEAP engine is built for long-term use. The turbine blades are made from strong materials. This helps them last longer and reduces the need for frequent replacements. It also ensures steady performance during the engine's life.

Next-Generation Engine Technology:

The LEAP engine is part of the next-generation engine technology that’s setting the standard for future aircraft propulsion systems. Designed to meet the demands of modern airlines, it provides high thrust-to-weight ratios while maintaining impressive fuel savings.

Airlines and aircraft manufacturers are increasingly choosing the LEAP engine for its exceptional performance, efficiency, and sustainability. It’s no wonder that CFM LEAP engines are now found in popular models like the Airbus A320neo and the Boeing 737 MAX. Here’s why the LEAP engine is the preferred choice:

Eco-Friendly and Cost-Effective:

The LEAP engine offers a significant reduction in fuel consumption and CO2 emissions, making it the ideal engine for airlines aiming to improve their environmental impact. At the same time, its efficiency helps airlines reduce fuel costs, which translates to long-term savings.

Reliability and Safety:

The CFM LEAP engines are known for their reliability. With enhanced turbine performance, the LEAP engine ensures consistent power and efficiency, providing airlines with peace of mind when it comes to engine reliability.

Industry Leading Materials and Technology:

Built with ceramic matrix composites and using advanced manufacturing techniques like the resin transfer molding process, the LEAP aircraft engine is at the forefront of engine innovation. These materials contribute to its strength, heat resistance, and lightweight structure, all of which improve performance.

As more airlines adopt the LEAP engine, CFM International continues to expand its production to meet the growing demand. The LEAP-1A engine and LEAP-1B engine have already garnered significant orders from major airlines globally.

High Demand from Global Airlines:

The increasing number of orders for LEAP engines indicates the trust that airlines have in this innovative engine. Leading carriers across the world are adopting the LEAP engine for its operational efficiency and performance.

Sustainable Aviation:

The LEAP engine is contributing to the future of sustainable aviation. As airlines face stricter environmental regulations, the LEAP engine’s low fuel consumption and reduced emissions make it the engine of choice for the eco-conscious airline industry.

Liyan International specializes in providing high-quality components for the LEAP aircraft engine.

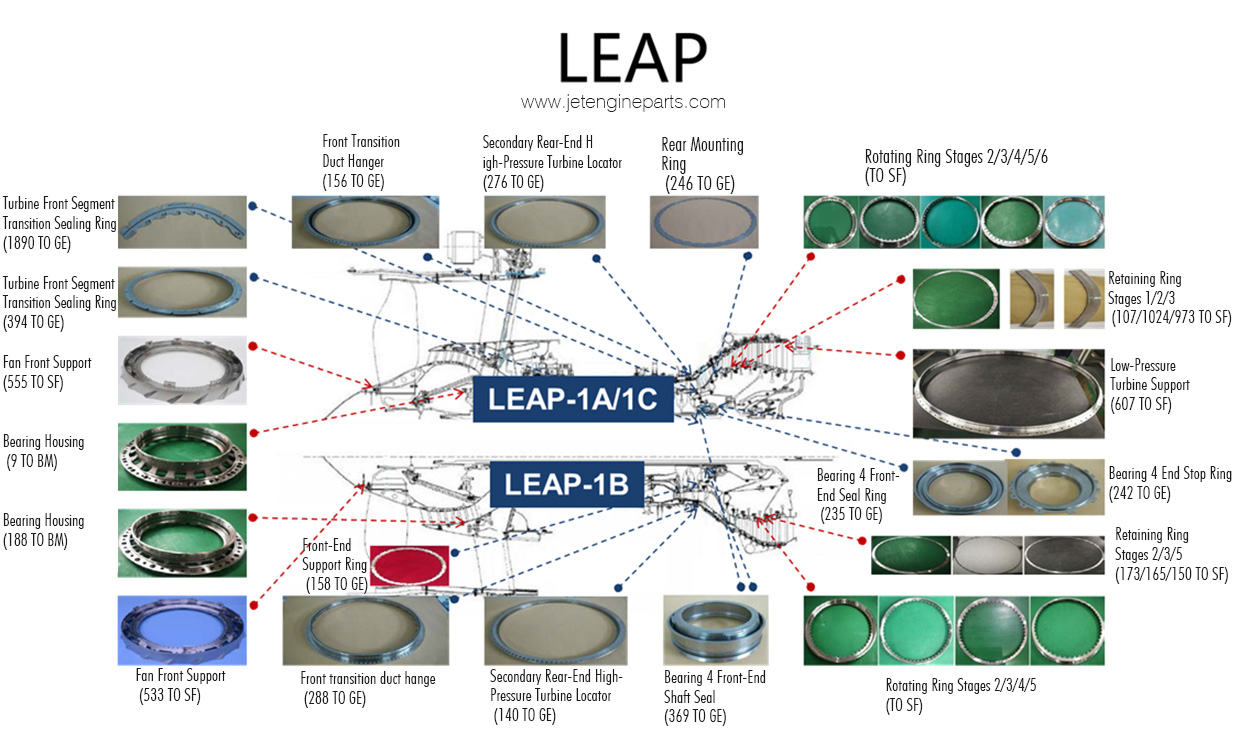

It supplies a wide range of components for the LEAP-1A, LEAP-1B, and LEAP-1C engines, including:

Front Transition Duct Hanger (156 TO GE): Ensures seamless airflow transition within the engine.

Turbine Front Segment Transition Sealing Ring (1890 TO GE / 394 TO GE): Maintains integrity of the turbine front segment.

Fan Front Support (555 TO SF / 533 TO SF): Provides stability to the fan blade assembly.

Bearing Housing (9 TO BM / 188 TO BM): Supports and aligns engine bearings.

Secondary Rear-End High-Pressure Turbine Locator (276 TO GE / 140 TO GE): Precisely positions the high-pressure turbine.

Rear Mounting Ring (246 TO GE): Secures rear-end components.

Rotating Ring Stages 2/3/4/5/6 (TO SF): Facilitates rotation across multiple turbine stages.

Retaining Ring Stages 1/2/3/5 (107/1024/973/173/165/150 TO SF): Secures various engine components.

Low-Pressure Turbine Support (607 TO SF): Stabilizes the low-pressure turbine assembly.

Front-End Support Ring (158 TO GE): Provides structural support to the engine's front end.

Bearing 4 Front-End Shaft Seal (369 TO GE): Prevents leakage around the shaft area.

Bearing 4 Front-End Seal Ring (235 TO GE): Ensures a tight seal for bearing 4.

Bearing 4 End Stop Ring (242 TO GE): Secures bearing 4 in position.

Liyan International uses advanced materials like ceramic matrix composites. They also use processes such as resin transfer molding. This ensures that each part meets the high standards of modern aviation. These innovations contribute to the LEAP engine's reputation for reliability and efficiency.

Liyan International's comprehensive range of LEAP engine components plays a crucial role in the success of modern aircraft. Liyan International follows high standards of quality and innovation. This helps improve the aerospace industry. We make sure each flight hour is efficient and reliable.

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat