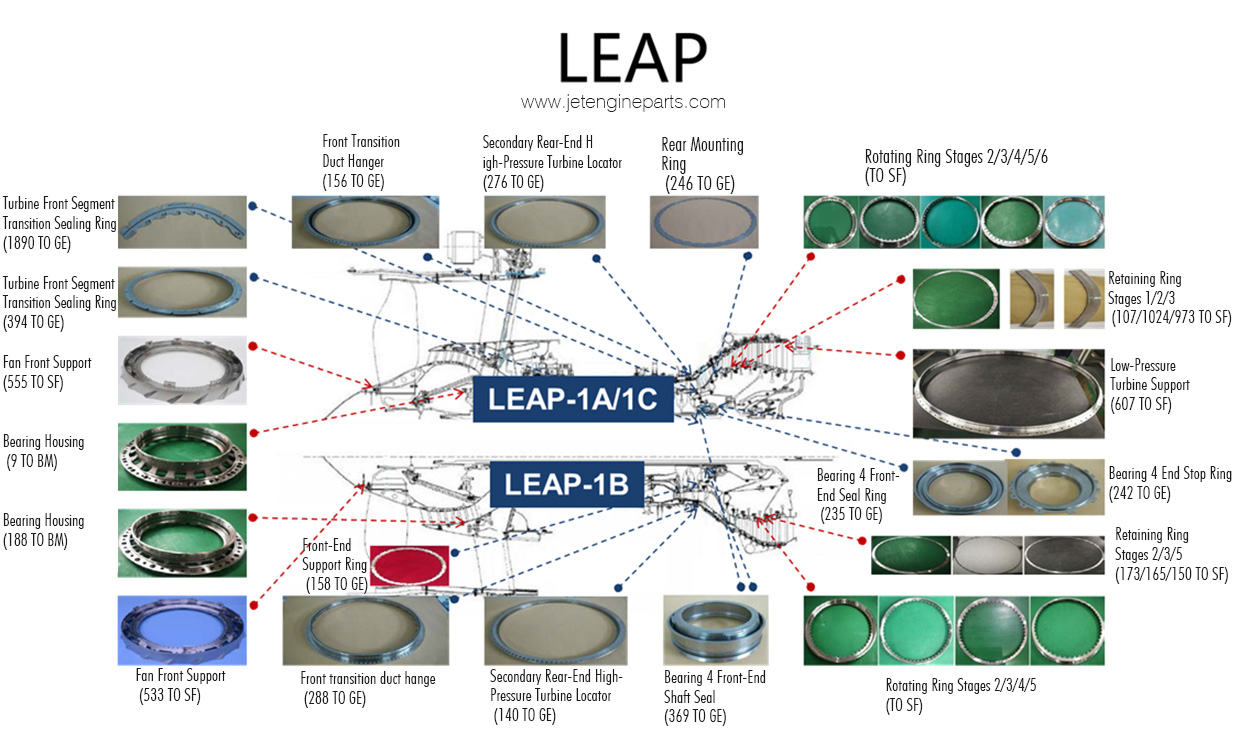

The Turbine Front Segment Sealing Ring is an essential component designed for LEAP-1A/1C engines, ensuring maximum engine efficiency and safety. This precision-engineered sealing ring optimizes airflow, minimizes leakage, and supports the high-performance operation of modern aircraft engines. Crafted from advanced materials like Ceramic Matrix Composites (CMC), it offers durability, resistance to extreme temperatures, and long service life. Suitable for cutting-edge aircraft such as the Airbus A320neo and COMAC C919, this sealing ring is a vital part of sustainable and efficient aviation technology.

The Turbine Front Segment Sealing Ring is an integral component of the LEAP-1A/1C engines, developed to meet the exacting demands of modern aviation. As part of the renowned LEAP engine series, this sealing ring plays a crucial role in ensuring operational efficiency, safety, and durability. Its precise engineering reflects the advanced technology that powers next-generation aircraft like the Airbus A320neo.

The Turbine Front Segment Sealing Ring is a critical aviation part designed to create a secure seal within the turbine's front segment. By maintaining airtight integrity, it optimizes the engine's pressure dynamics, enhancing fuel efficiency and overall performance. This sealing ring is specifically crafted for LEAP-1A and LEAP-1C engines, which are widely recognized for their reliability and sustainability in the aviation industry.

Key functions of the Turbine Front Segment Sealing Ring include:

Maintaining Pressure Integrity

By preventing air leakage in the turbine's front segment, the sealing ring ensures optimal pressure conditions, contributing to efficient fuel combustion.

Reducing Wear and Tear

Its robust design minimizes friction between components, extending the engine's lifespan and reducing maintenance needs.

Enhancing Engine Efficiency

The sealing ring supports smoother airflow within the engine, directly improving thrust and reducing fuel consumption.

The Turbine Front Segment Sealing Ring is manufactured using advanced materials like ceramic matrix composites (CMC) and high-performance alloys. These materials are chosen for their:

Durability: Withstanding extreme temperatures and pressures in the turbine.

Corrosion Resistance: Ensuring long-term reliability in varying operating conditions.

Lightweight Properties: Reducing overall engine weight to enhance fuel efficiency.

The precision-engineered design ensures a perfect fit within the LEAP-1A and LEAP-1C engines, maintaining structural stability during high-stress operations.

A secure turbine seal prevents potential hazards caused by air leakage or component misalignment. This makes it a key part of the LEAP engines' reputation for safety.

By reducing wear on the turbine, the sealing ring lowers long-term maintenance costs for airlines. Its contribution to fuel efficiency also reduces operating expenses.

The sealing ring is designed to meet strict aviation regulations for noise, emissions, and operational performance. It helps airlines comply with global environmental standards while maintaining high efficiency.

The LEAP-1A/1C engines, developed by CFM International, are widely used in commercial aviation. These engines power aircraft such as the Airbus A320neo and the COMAC C919, offering unmatched performance and sustainability. The Turbine Front Segment Sealing Ring plays a pivotal role in these engines by:

Optimizing fuel efficiency during long-haul and short-haul flights.

Ensuring smooth operations under varying environmental conditions.

Supporting the engine's thrust-to-weight ratio, crucial for modern aircraft design.

The Turbine Front Segment Sealing Ring contributes to better airflow and combustion, resulting in improved engine performance.

Its durable construction ensures that the engine operates at peak performance for extended periods, reducing downtime and replacement needs.

By improving fuel efficiency and reducing emissions, the sealing ring aligns with the aviation industry's commitment to sustainability and eco-friendly practices.

At Liyan International, we specialize in supplying high-quality components for LEAP-1A/1C engines, including the Turbine Front Segment Sealing Ring. Our commitment to precision and quality ensures that our parts meet the highest industry standards, delivering reliability and efficiency for modern aviation.

Advanced Manufacturing: Our components are crafted using cutting-edge materials and techniques.

Global Trust: Airlines and manufacturers worldwide rely on our parts for their fleets.

Customer-Centric Approach: We provide tailored solutions to meet the unique needs of our clients.

As the aviation industry prioritizes sustainability, components like the Turbine Front Segment Sealing Ring are vital. By improving fuel efficiency and reducing emissions, this component supports airlines in meeting environmental goals while maintaining high operational standards.

The Turbine Front Segment Sealing Ring is more than just a component—it’s a critical enabler of modern aviation's efficiency, reliability, and sustainability. Its role in the LEAP-1A/1C engines underscores the importance of precision-engineered parts in powering next-generation aircraft.

For airlines and operators seeking top-quality aviation components, Liyan International offers unparalleled expertise and reliability. Contact us today to learn more about our comprehensive range of LEAP-1A/1C components, including the Turbine Front Segment Sealing Ring, and discover how we can support your aviation needs.

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat