The Turbine Front Segment Transition Sealing Ring is a high-performance flight engine part designed for LEAP-1A and LEAP-1C engines. It ensures airtight containment of high-temperature gases in the turbine front segment, minimizing pressure loss and enhancing engine efficiency. Manufactured from aerospace-grade alloys and precision-machined for tight tolerances, this sealing ring helps extend engine life and reduce maintenance downtime.

For jet propulsion, small components often have outsized impacts. One of the most overlooked yet mission-critical flight engine parts is the turbine front segment transition sealing ring. Especially the 394 TO GE model used in LEAP-1A/1C engines.

Many aviation professionals, like MRO teams and aircraft engine OEMs, often focus on fan blades, turbines, or fuel systems. However, without precision-sealed transitions between engine stages, pressure loss, heat distortion, and fuel inefficiency will follow. And with modern jet engines, even minor inefficiencies can cost millions annually.

That's why choosing the right engine parts is more than a supply decision. It's a strategy to safeguard performance, extend engine life, and reduce downtime.

The sealing ring is a transition component located in the turbine front segment of a LEAP-1A or LEAP-1C engine. Its main job is to seal the boundary between rotating and stationary engine parts where hot, high-pressure gases pass through from the combustor into the turbine section.

Designed from heat-resistant aerospace alloys, this sealing ring ensures that combustion gases stay pressurized, focused, and contained within the correct aerodynamic path. If this seal fails, not only does the pressure drop, but adjacent components suffer from thermal erosion and mechanical fatigue.

Preventing hot gas leakage from combustion chambers

Ensuring consistent turbine temperature profiles

Supporting stable rotor and stator alignment

Reducing vibration and mechanical stress

In a LEAP-1A/1C aircraft engine, the sealing ring sits at the front of the high-pressure turbine (HPT), just behind the combustor. Here, the engine is at peak thermal and mechanical stress, with temperatures exceeding 1,500°C (2,700°F) and pressures reaching 30–40 atmospheres.

In this zone, metal expansion, gas turbulence, and vibration collide. Only components like the ring—engineered with exact tolerances and fatigue-resistant materials—can survive and function under these conditions.

Many engine operators have learned the hard way: not all sealing rings are created equal. Choosing a cheaper or unverified substitute can lead to:

Improper sealing leads to unwanted pressure release, decreasing engine thrust.

Without consistent airflow control, turbines overheat and blade tips warp.

Leaks stress nearby engine parts, shortening maintenance intervals.

Uncertified engine parts often fail to meet FAA/EASA airworthiness standards.

In fact, for fleets using high-efficiency aircraft engines like LEAP-1A/1C, replacing a failed sealing ring can cost far more in labor, delay penalties, and component damage than sourcing the correct part in the first place.

The turbine front segment transition sealing ring is not just another circular metal component. It is a precision-engineered flight engine part developed to handle some of the most extreme conditions in modern airplane engine operation. Positioned in a zone of intense heat, pressure, and rotational turbulence, this part demands multi-disciplinary design excellence—and it delivers exactly that.

It merges aerospace-grade metallurgy, fluid dynamics, and thermal-mechanical engineering to create a sealing solution that preserves thrust, protects components, and improves the overall efficiency of the aircraft engine.

The sealing ring is crafted from advanced nickel-based superalloys, specifically selected for their ability to:

Withstand temperatures exceeding 1,500°C (2,732°F)

Resist oxidation, even after thousands of thermal cycles

Prevent creep deformation during long-duration high-stress flights

Maintain structural integrity under vibration and dynamic loads

This makes the ring highly reliable in both short-haul commercial aircraft and high-frequency mission profiles where engine parts must perform under repeated thermal shock and load variation.

The sealing ring is CNC-machined using 5-axis equipment and laser inspection tools to achieve micron-level tolerances. Why is this critical?

A perfect seal ensures no high-pressure gas leakage, maintaining turbine efficiency

It guarantees consistent airflow and temperature distribution, preventing hot spots

Precision manufacturing reduces assembly time, enabling easier drop-in replacement in OEM or MRO settings

This meticulous machining also prevents fitting errors, which are common causes of seal failure and unexpected maintenance events.

One of the most impressive features of the 394 TO GE is its built-in thermal adaptability. The ring's geometry is engineered to expand and contract in unison with the surrounding engine casing, even during rapid throttle changes.

The ring includes flexible contours and pressure-absorbing ridges that accommodate dimensional shifts

This ensures the ring maintains tight contact and sealing efficiency across the full range of engine operations

It minimizes metal-to-metal rubbing or stress fractures, a common issue in low-quality substitutes

This attribute is vital in LEAP engines, where thermal gradients can change rapidly between flight phases, particularly between climb and cruise.

The 394 TO GE is fully compatible with LEAP-1A and LEAP-1C engine assemblies, making it a true plug-and-play component:

No modifications or additional tooling required

Fits directly into the turbine front segment during original build or overhaul

Compatible with OEM part numbers and engineering documentation

Traceable and compliant with AS/EN 9100, FAA, and EASA certification standards

This compatibility not only simplifies procurement for airplane parts suppliers, but also lowers risk for maintenance engineers and part integrators.

Thanks to the combination of durable material, thermal resilience, and dimensional accuracy, the sealing ring offers longer time-on-wing compared to generic alternatives.

Fewer replacements needed during heavy checks

Minimizes downtime during C-checks and D-checks

Maintains seal performance over multiple cycles without needing constant adjustment

This translates to lower total cost of ownership and a higher return on investment for fleet operators.

Finally, the sealing ring doesn't just “seal.” It actively supports:

Turbine efficiency, by directing flow and pressure where it matters

Fuel economy, by preventing loss of combustion pressure

Reduced CO₂ emissions, by preserving thermodynamic balance

Component protection, by isolating turbine segments from erratic heat distribution

For those who manage flight engine parts with long-term fleet performance in mind, this sealing ring plays a small yet vital role in achieving maximum reliability and sustainability.

Today's aircraft engines are built for longer flight cycles, higher bypass ratios, and better fuel economy. But this performance comes at a price: higher internal pressures, narrower tolerances, and a greater reliance on thermal efficiency.

Sealing rings like the 394 TO GE are no longer “optional insurance.” They're essential components in preserving the integrity and output of the entire engine. Every kilopascal of pressure retained, and every degree of temperature managed, contributes to:

Reduced fuel burn

Fewer maintenance events

Lower carbon emissions

Safer, smoother flight

And that's what today's airlines—and their customers—demand.

Not all airplane engine components are created equal—especially when operating under extreme thermal, mechanical, and environmental stress. At Liyan International, we specialize in precision-manufactured flight engine parts, with a dedicated line for LEAP-1A/1C engines.

We understand the stakes. That's why every turbine sealing ring we supply is:

CNC-machined to OEM specifications

Non-destructively tested (NDT)

Accompanied by full documentation and traceability

Ready for global airworthiness compliance (FAA, EASA)

Whether you're a large airline operating an Airbus A320neo fleet or an MRO team trying to avoid engine removal, you need engine parts that fit, perform, and last.

Faster delivery than OEM lead times

Affordable pricing without sacrificing quality

Engineering support for application and replacement

Secure packaging for international logistics

When you source LEAP-1A/1C engine parts from Liyan, you're partnering with a flight engine parts expert, not just a parts reseller.

Wondering who benefits most from this part?

This high-performance sealing ring is ideal for:

Replace worn or degraded sealing rings during scheduled turbine module inspections without full engine teardown.

Integrate into LEAP-1A/1C production programs to streamline sourcing and control part costs.

Use as a drop-in replacement when rebuilding LEAP engines for extended service life.

Expand your inventory with certified components that meet the rising demand for LEAP-compatible replacements.

In all these cases, Liyan provides not just product, but consulting-level guidance to ensure seamless integration into your operations.

At Liyan International, we don't just supply parts—we deliver a complete ecosystem of high-performance aerospace components tailored for the industry's most advanced commercial jet engines, including the LEAP-1A/1C and LEAP-1B platforms.

Our clients—ranging from OEM assembly lines to global MRO hubs—choose us not only for quality but also for reliability, documentation, and deep technical support. Every component we offer comes with full traceability, NDT inspection, and compatibility assurance, ensuring it integrates seamlessly into your existing engine architecture.

Whether you're managing a large airline fleet or a dedicated engine maintenance facility, our parts help you streamline sourcing, reduce downtime, and maintain flight-readiness.

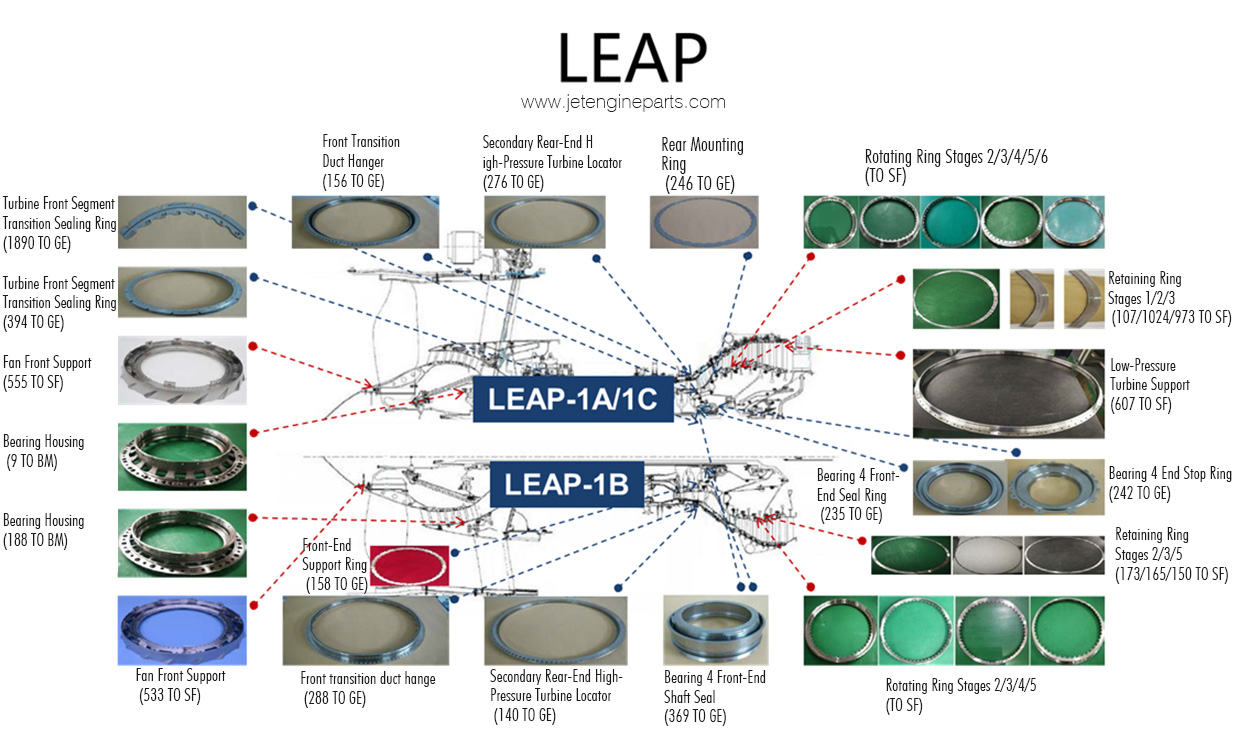

These high-bypass turbofan engines power aircraft like the Airbus A320neo and rely on precision components to handle extreme operating conditions. Our key offerings include:

Front Transition Duct Hanger (156 TO GE): Supports the smooth transition of airflow from the fan to the compressor, helping to maintain pressure stability.

Turbine Front Segment Transition Sealing Ring (1890 TO GE / 394 TO GE): Prevents hot gas leakage at the turbine's leading edge, ensuring optimal pressure and temperature containment.

Fan Front Support (555 TO SF): A structural anchor for the fan module that ensures balanced rotation and vibration damping during high-RPM flight cycles.

Bearing Housing (9 TO BM): Provides concentric support and secure alignment for internal engine bearings, maintaining rotor shaft precision.

Secondary Rear-End High-Pressure Turbine Locator (276 TO GE): Ensures accurate turbine alignment to reduce aerodynamic loss and extend turbine blade life.

Rear Mounting Ring (246 TO GE): Strengthens the engine's rear section and acts as a key connection point between modules.

Rotating Ring Stages 2/3/4/5/6 (TO SF): Maintains rotation efficiency and load transfer through multiple turbine stages, supporting consistent thrust.

Retaining Ring Stages 1/2/3 (107/1024/973 TO SF): Locks critical turbine components securely into place under extreme axial loads.

Low-Pressure Turbine Support (607 TO SF): Provides structural balance and vibration control for the low-pressure turbine (LPT) assembly, reducing mechanical wear.

The LEAP-1B engine, used on the Boeing 737 MAX series, shares design principles with LEAP-1A/1C but includes unique parts. We provide full coverage for the LEAP-1B as well:

Bearing Housing (188 TO BM): Delivers precise bearing alignment and shock absorption in the core shaft structure.

Front Transition Duct Hanger (288 TO GE): Optimizes airflow and minimizes turbulence in the fan-to-compressor zone.

Front-End Support Ring (158 TO GE): Provides structural integrity and balance to the front section of the engine core.

Fan Front Support (533 TO SF): Ensures stable operation of the fan assembly, absorbing vibration and preventing imbalance during rotation.

Secondary Rear-End High-Pressure Turbine Locator (140 TO GE): Assures correct turbine positioning, essential for maintaining turbine module alignment and efficiency.

Rotating Ring Stages 2/3/4/5 (TO SF): Transfers rotational forces and supports turbine blade synchronization during operation.

Bearing 4 Front-End Seal Ring (235 TO GE): Prevents oil and gas leakage around the front-end bearing housing, maintaining lubrication integrity.

Bearing 4 End Stop Ring (242 TO GE): Holds the bearing assembly in place under axial stress, increasing mechanical reliability.

Retaining Ring Stages 2/3/5 (173/165/150 TO SF): Locks key components of the turbine under pressure, ensuring secure placement during engine operation.

Some components serve both LEAP-1A/1C and LEAP-1B engines, simplifying your inventory and procurement process:

Bearing 4 Front-End Shaft Seal (369 TO GE): Critical for preventing lubricant loss and contamination, protecting the shaft in high-speed environments.

Consistent OEM compatibility for all flight engine parts

Rapid global delivery with airfreight and bonded warehousing options

Full quality documentation, including dimensional checks, material traceability, and compliance reports

Real-time engineering support, whether for part selection or installation guidance

With Liyan International, you're not just buying airplane engine components—you're gaining a supply chain partner who speaks your language, meets your deadlines, and supports your technical needs from quote to flight.

Most engine part providers sell whatever is available. Liyan does things differently.

We focus on:

Only high-demand flight engine parts

Quality inspection at every stage

Engineer-to-engineer service

Continuous improvement through client feedback

Instead of generic catalogs, we tailor our offerings to exactly what engine managers, technicians, and purchasing agents actually need. You won't waste time sorting through irrelevant items or waiting weeks for a reply.

Your aircraft engine deserves better than guesswork. When you call Liyan, you get access to professionals who know the LEAP engine architecture inside and out.

We'll help you:

Match part numbers and subcomponent variants

Review test reports and tolerances

Calculate estimated lead times

Arrange sample shipments or bulk quotes

Provide application drawings or manuals if needed

No generic responses. No delays. Just real support for real professionals.

Whether you're sourcing for routine maintenance, a fleet overhaul, or a new build program, the 394 TO GE sealing ring is a critical part of your success.

Let's make sure you get it right.

Contact us now to:

Receive pricing for your required quantity

Request material certificates and inspection reports

Get detailed specs or request samples

Schedule a consultation with our technical team

Liyan International — your partner for precision flight engine parts.

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat