The Fan Front Support (555 TO SF) is a precision-engineered structural component for LEAP-1A/1C aircraft engines. Designed to stabilize and align the fan blade assembly, it ensures efficient thrust generation and safe engine performance under extreme flight conditions. Built from aerospace-grade materials and tested to AS standards, this support is vital for maintaining engine reliability.

Precision Aircraft Parts from Trusted Airplane Parts Suppliers

Aircraft engines endure extreme operational stresses. For professionals in maintenance, repair, and overhaul (MRO) or OEM procurement, structural instability is a nightmare. Even a minor misalignment in the fan module can result in severe imbalances, vibration, and premature wear—leading to high costs and safety risks.

That’s why choosing high-precision components from experienced airplane parts suppliers is critical. Among these, the Fan Front Support (555 TO SF) for LEAP-1A/1C engines plays a fundamental role.

The Fan Front Support (555 TO SF) is a critical aerospace component used in LEAP-1A and LEAP-1C aircraft engines. Its primary function is to structurally support the front section of the engine’s fan module, where most of the engine’s thrust is generated.

Positioned between the fan case and the engine’s core structure, this support frame serves multiple vital purposes:

Stabilizes the fan blade assembly under high rotational speeds

Transfers mechanical loads from the fan to the engine frame

Maintains axial alignment, ensuring smooth rotation of key moving parts

Helps guide airflow, contributing to overall engine efficiency

Manufactured from high-strength aerospace alloys, the 555 TO SF must withstand extreme thermal and mechanical stress during takeoff, cruise, and landing. Its design ensures the fan remains centered and securely attached—even during high-vibration events or sudden thrust changes.

Without this component, an engine could experience dangerous imbalances, bearing damage, or fan blade failure, making it one of the most critical structural parts in the LEAP-1A/1C engine architecture.

In LEAP-series engines, the fan section alone produces up to 85% of total thrust, making it the most powerful and dynamic module within the entire engine system. The Fan Front Support (555 TO SF) serves as the structural anchor for this high-speed assembly. Its job is to keep the fan case, blades, and central shaft perfectly aligned while enduring constant stress and temperature variation.

During critical flight phases—takeoff, climb, cruise, and landing—the fan system is exposed to intense aerodynamic loads, torque, and rapid changes in RPM. The fan front support must hold firm against:

Axial and radial loading

Centrifugal forces from spinning blades

Thermal expansion from core heat

Vibrational harmonics from rotating components

If the support structure flexes, shifts, or deforms—even by a fraction of a millimeter—it can lead to:

Unbalanced fan blade rotation, resulting in engine wobble

Excessive vibration, increasing fatigue on surrounding components

Accelerated bearing wear, reducing operational lifespan

Decreased engine efficiency, leading to higher fuel consumption

Fan blade tip clearance deviation, which could cause rubbing or catastrophic blade failure

These risks are not hypothetical. In high-bypass turbofan engines like LEAP, any instability in the fan assembly compromises engine performance, fuel economy, and safety.

That’s why precision-engineered front supports—such as the 555 TO SF—are indispensable. They ensure structural integrity, enhance the reliability of the rotating assembly, and provide the confidence airlines and MRO providers demand.

This aerospace component is built using high-strength alloys designed to resist deformation under dynamic loads. Its geometry is tailored to distribute stress evenly, preventing fatigue failures during long flight cycles.

The 555 TO SF undergoes CNC machining processes to meet exact tolerances. This ensures accurate alignment between the fan blades, case, and shafts, reducing system vibration.

Thanks to its heat-resistant materials, the fan front support maintains dimensional integrity under extreme temperatures. This is vital during continuous takeoff and climb conditions.

The support transfers aerodynamic and structural loads from the fan into the engine case. Without this, surrounding components would suffer premature fatigue or failure.

At Liyan International, we understand the pressure aviation professionals face. Aircraft downtime, compliance issues, and sourcing delays can stall entire operations.

That’s why we focus on delivering certified aerospace components that integrate perfectly with engine systems, especially for LEAP platforms. Our Fan Front Support (555 TO SF) is produced under stringent AS9100 standards and verified with non-destructive testing (NDT).

When you choose Liyan, you're not just buying parts—you’re investing in reliability.

At Liyan International, we specialize in providing vital components for both the LEAP-1A/1C and LEAP-1B engines. We’ve built our reputation by serving clients who value consistency, traceability, and technical support.

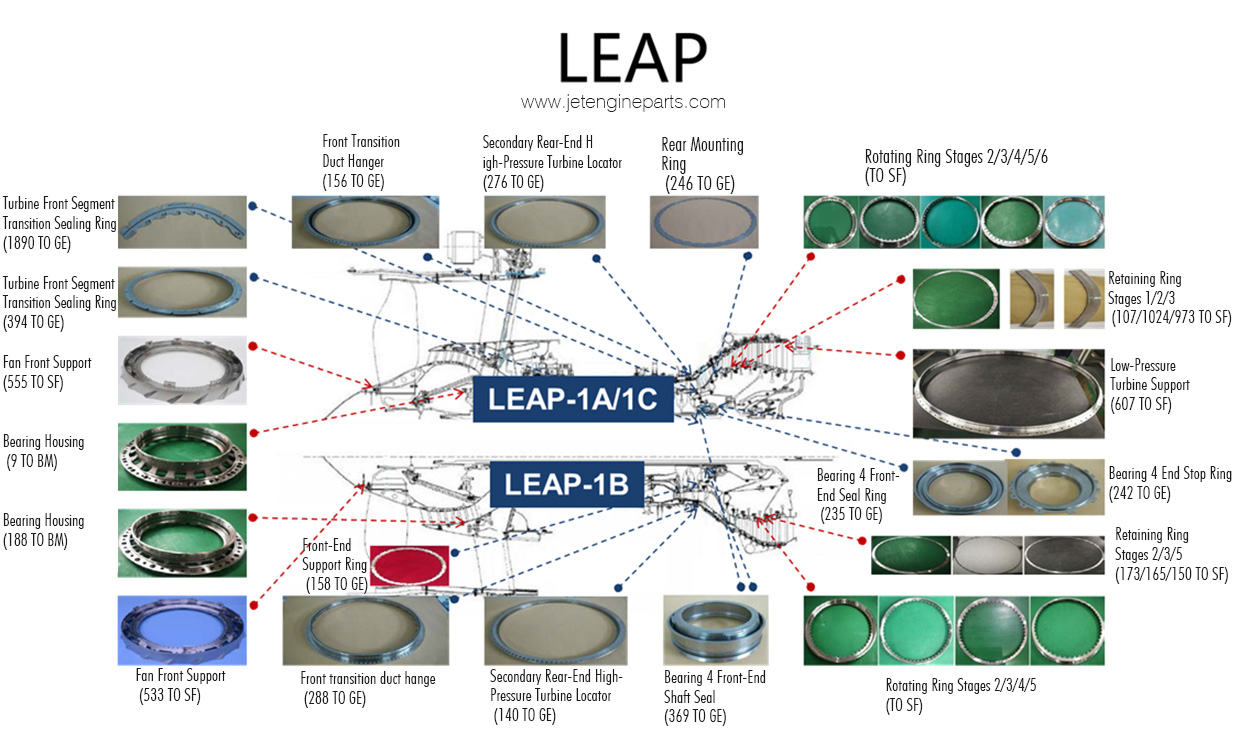

Front Transition Duct Hanger (156 TO GE): Supports the smooth transition of airflow.

Turbine Front Segment Transition Sealing Ring (1890 TO GE / 394 TO GE): Seals and protects the turbine's front segment.

Fan Front Support (555 TO SF): Ensures stability for the fan blade.

Bearing Housing (9 TO BM): Provides support and alignment for bearings.

Secondary Rear-End High-Pressure Turbine Locator (276 TO GE): Positions the high-pressure turbine for optimal performance.

Rear Mounting Ring (246 TO GE): Provides support for rear-end assembly.

Rotating Ring Stages 2/3/4/5/6 (TO SF): Enhances rotation for various turbine stages.

Retaining Ring Stages 1/2/3 (107/1024/973 TO SF): Locks critical components securely in place.

Low-Pressure Turbine Support (607 TO SF): Stabilizes the low-pressure turbine assembly.

Bearing Housing (188 TO BM): Supports internal bearings and shafts.

Front Transition Duct Hanger (288 TO GE): Supports airflow transition in the front section.

Front-End Support Ring (158 TO GE): Provides stability to the engine's front section.

Fan Front Support (533 TO SF): Maintains balance and support for the fan blade.

Secondary Rear-End High-Pressure Turbine Locator (140 TO GE): Precisely positions the turbine's rear section.

Rotating Ring Stages 2/3/4/5 (TO SF): Improves turbine rotation for multiple stages.

Bearing 4 Front-End Seal Ring (235 TO GE): Protects the front-end bearings.

Bearing 4 End Stop Ring (242 TO GE): Secures the bearing assembly.

Retaining Ring Stages 2/3/5 (173/165/150 TO SF): Holds turbine components firmly in place.

Bearing 4 Front-End Shaft Seal (369 TO GE): Protects and seals the shaft in the engine's critical areas.

Procurement teams often struggle with inconsistent quality, slow delivery, or unclear documentation. At Liyan, we solve these problems through:

| Challenge | Liyan’s Solution |

|---|---|

| Delays in delivery | Global warehouse network for expedited shipping |

| Inconsistent specifications | Full documentation and serial number traceability |

| Complex part validation | All items AS-standard tested and NDT-certified |

| Lack of technical support | Direct engineer access and pre-sale consultation |

Many suppliers offer parts. Few offer long-term peace of mind. Our commitment to component precision, quality verification, and application support has made us a trusted partner for clients worldwide.

We serve:

Commercial aircraft fleets

MRO facilities

Parts distributors

OEM assembly lines

If you're tired of overpriced quotes, vague certifications, and long waits—Liyan International is ready to change that experience.

Are you ready to source a precision-crafted fan front support that meets your LEAP-1A/1C program requirements?

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat