The Bearing Housing is a precision machined aerospace component designed for LEAP-1A and LEAP-1C engines. Built from high-strength, heat-resistant alloys, this part ensures exact bearing alignment, reduces vibration, and supports long-term engine stability under extreme thermal and mechanical conditions. Ideal for OEMs and MRO providers seeking certified, high-performance engine support components.

The bearing housing is a precision-engineered aerospace component used in the LEAP-1A and LEAP-1C turbofan engines. It serves as the structural cradle that supports the internal bearings. It also precisely aligns them to stabilize the rotating shafts that drive the engine’s core modules.

Without this housing, the bearings cannot maintain proper alignment. This leads to imbalanced rotation, increased friction, and mechanical breakdown over time.

This component occupies one of the most stress-intensive sections of the engine. It must withstand enormous centrifugal forces and high thermal gradients. At the same time, it must handle rapid pressure changes while keeping the bearings fixed in micrometer-level precision.

The housing is typically made from high-strength, heat-resistant alloys. We machine it to exact tolerances to meet the dynamic demands of high-bypass jet engines like the LEAP-1A/1C.

Simply put, the 9 TO BM bearing housing is a foundational part of the engine’s mechanical integrity. It ensures that the internal motion of the engine remains smooth, stable, and efficient across thousands of flight cycles.

Bearing alignment is not visible to the naked eye. Yet it plays a crucial role in engine performance, safety, and service life. In high-speed engines like the LEAP-1A/1C, even a slight misalignment in the bearing housing is dangerous. It can place excessive axial or radial loads on the shaft.

This causes harmful vibrations and uneven wear. It also leads to overheating, which shortens component life and increases maintenance costs.

Proper alignment through a well-made bearing housing like the 9 TO BM is essential. It ensures even load distribution across all bearings. This minimizes frictional resistance, reduces energy loss, and improves the engine’s thermal balance.

More importantly, it protects other components from stress. These include turbine blades, oil seals, and rotor assemblies.

In short, a precisely aligned bearing housing keeps the engine running smoother, quieter, and longer. It is not just a support structure. It is a key performance enabler and a safety feature for every LEAP-powered flight.

We designed the bearing housing specifically for harsh operating conditions. These conditions exist in the core of LEAP-1A and LEAP-1C engines. Its design includes several advanced engineering features. These ensure both durability and precision through thousands of flight cycles.

First, the material selection is critical. We manufacture the housing from aerospace-grade alloys like nickel or titanium. These provide strength, heat resistance, and minimal thermal expansion. These materials allow the housing to maintain structural integrity even under operating temperatures exceeding 1,000°F (538°C).

Second, Our design team prioritizes fatigue resistance when developing this component. The housing shape includes special contours to relieve stress. It also directs load paths to prevent fatigue cracks during repeated use. This makes it ideal for high-cycle engines like the LEAP-1A/1C.

Finally, the manufacturing tolerances are extremely tight. Our machining team uses five-axis CNC equipment to achieve ±0.005 mm precision in each bearing housing. This ensures exact bearing alignment, reduced shaft deflection, and consistent oil clearance during high-speed operation.

These design features are not optional—they are essential. These design elements ensure optimal performance, safety, and engine lifecycle. Without them, the engine suffers from serious operational risks.

Choosing the wrong supplier for aerospace components can lead to catastrophic outcomes. Low-quality bearing housings often lack the dimensional accuracy, material purity, and fatigue performance required for aviation use. The consequences are both costly and dangerous.

One of the most common issues is misalignment, which creates unbalanced shaft rotation. This leads to high vibration levels. It also causes early bearing wear and damages nearby seals and rotors.

Another failure is thermal deformation. This occurs when poor materials lose their shape under heat, leading to seal leaks and poor lubrication.

Porosity or hidden cracks in low-quality housings are another issue. Over time, these flaws grow and can cause sudden mechanical failure. In the worst case, this can shut down the engine. It may force an in-flight return or ground the aircraft—something no airline wants.

These failures aren't hypothetical. MRO shops and OEMs worldwide have reported higher costs. Many of these are due to substandard or counterfeit bearing housings.

The takeaway is simple: When it comes to bearing housings, precision saves lives and money. Always source from qualified airplane parts suppliers with verifiable certifications and testing procedures.

At Liyan, we understand that a bearing housing is more than just a machined part—it's a mission-critical component. That is why we follow a strict quality control process. Each housing goes through several inspection stages.

Our process starts with material certification. We only use alloys from trusted aerospace mills with full traceability. The materials then undergo CNC machining in our ISO/AS9100-certified production facility using automated tool-path verification software.

Our quality control specialists perform dimensional inspections on every housing using coordinate measuring machines (CMMs) to confirm micron-level tolerances. For added safety, we perform non-destructive testing (NDT), including ultrasonic and dye penetrant inspections, to detect subsurface flaws.

Our engineers run thermal cycling tests to confirm the housing’s stability under real-world engine conditions. Additionally, we provide full documentation, including CoC (Certificate of Conformity), test results, and optional 3D digital scans for MRO traceability.

With Liyan International, you’re not just purchasing a part—you’re gaining a reliable partner in engine performance. Our customers trust us for one reason. We deliver parts that meet or exceed OEM standards without delays or surprise costs.

In modern aviation, safety and fuel efficiency are no longer competing priorities—they’re partners in performance. Aviation professionals around the world praise LEAP-1A/1C engines for their efficiency and low emissions. But real performance gains come from internal components like the 9 TO BM bearing housing.

This component, though compact, plays a disproportionate role in engine efficiency. By maintaining tight bearing alignment and minimizing shaft deflection, it reduces internal friction and stabilizes oil flow. These components allow smoother cycles and better heat management. They also reduce internal friction, which lowers fuel use per mile.

On the safety side, the bearing housing protects the engine from potential misalignment disasters. It acts as a thermal and mechanical buffer, keeping the shaft centered during rapid throttle changes and atmospheric fluctuations. A failure here doesn’t just increase maintenance—it could compromise structural integrity.

Many procurement managers focus on headline components like turbines or combustors. The housings, seals, and rings may seem minor. Yet they often decide if an engine runs at 98% efficiency or suffers rapid wear.

In other words: reliable aerospace components maximize profit while minimizing risk.

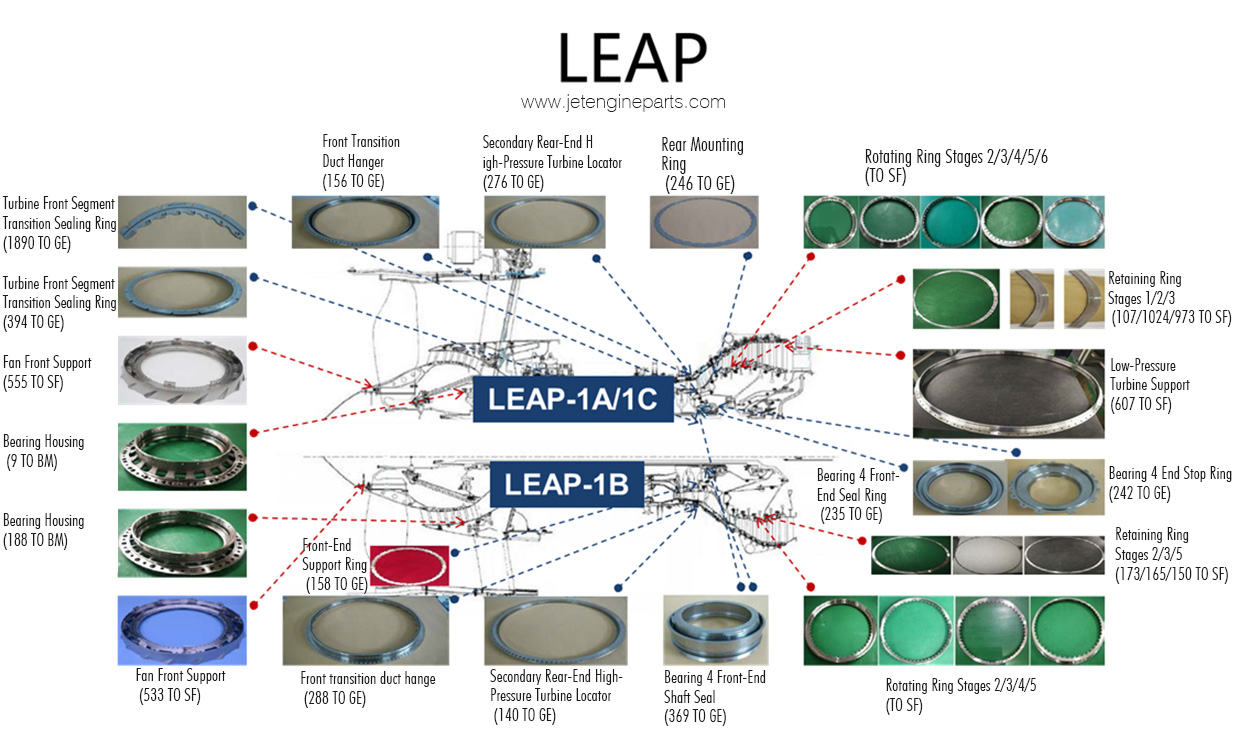

The LEAP-1A/1C and LEAP-1B engines are structurally similar. But they require different bearing housings in key ways. These differences matter greatly to procurement specialists and engineers sourcing replacement components or stocking MRO inventory.

The housing in LEAP-1A/1C engines is highly specific. It matches shaft geometry used in Airbus narrowbody jets. Its design includes tailored angles and oil flow channels. We designed it to handle vibration from A320neo aircraft loads.

The housing in LEAP-1B engines is different. It has unique mounting points, cooling designs, and internal pressure specs. It also integrates differently with accessory gearbox layouts.

While the two components may appear interchangeable in basic dimensions, their performance under load diverges dramatically. Using the wrong housing—even if it “fits”—could lead to oil seal leakage, misalignment, or unexpected wear patterns.

That’s why smart buyers choose airplane parts suppliers like Liyan International. We provide the correct part number, technical drawings, and installation support. Our clients never worry about misapplication—because we help you choose precisely what your engine demands.

At Liyan International, we specialize in providing vital aerospace components for the aviation industry. Our product range includes precision parts for both LEAP-1A/1C and LEAP-1B engines.

Front Transition Duct Hanger (156 TO GE): Supports the smooth transition of airflow.

Turbine Front Segment Transition Sealing Ring (1890 TO GE / 394 TO GE): Seals and protects the turbine's front segment.

Fan Front Support (555 TO SF): Ensures stability for the fan blade.

Bearing Housing (9 TO BM): Provides support and alignment for bearings.

Secondary Rear-End High-Pressure Turbine Locator (276 TO GE): Positions the high-pressure turbine for optimal performance.

Rear Mounting Ring (246 TO GE): Provides support for rear-end assembly.

Rotating Ring Stages 2/3/4/5/6 (TO SF): Enhances rotation for various turbine stages.

Retaining Ring Stages 1/2/3 (107/1024/973 TO SF): Locks critical components securely in place.

Low-Pressure Turbine Support (607 TO SF): Stabilizes the low-pressure turbine assembly.

Bearing Housing (188 TO BM): Provides support and alignment for bearings.

Front Transition Duct Hanger (288 TO GE)

Front-End Support Ring (158 TO GE)

Fan Front Support (533 TO SF)

Secondary Rear-End High-Pressure Turbine Locator (140 TO GE)

Rotating Ring Stages 2/3/4/5 (TO SF)

Bearing 4 Front-End Seal Ring (235 TO GE)

Bearing 4 End Stop Ring (242 TO GE)

Retaining Ring Stages 2/3/5 (173/165/150 TO SF)

Bearing 4 Front-End Shaft Seal (369 TO GE): Protects and seals the shaft in the engine’s critical areas.

In the aviation industry, trust isn't just earned through certifications—it's built through consistency, responsiveness, and technical reliability. At Liyan International, we’ve worked with MROs and OEMs for years. Our aerospace components consistently meet high-performance needs.

So, what sets us apart from other airplane parts suppliers?

Technical Precision: Our team machines each LEAP-1A/1C bearing housing to exacting tolerances and tests them under simulated engine conditions.

Comprehensive Documentation: Every shipment includes Certificates of Conformity, dimensional inspection reports, and optional 3D CAD data—ready for your engineering records or regulatory audits.

Global Logistics Network: Our global logistics partners ensure fast delivery. This applies whether your facility is in North America, Europe, or the Middle East.

Responsive Support: From AOG support to bulk orders, we’re here to help. Our multilingual team does more than sell parts—they solve problems.

Maintenance professionals value consistency. Procurement teams value transparency. Our job is to deliver both.

Working with Liyan International means more than buying. It means partnering with people who speak your language and support your mission.

Downtime costs money. Misaligned components risk safety. Delayed delivery can damage your entire MRO schedule.

If you're ready to improve engine reliability and reduce surprises, act now. Don’t wait for a failure to force the decision.

Liyan International’s bearing housing is ready to ship. We build it with aerospace-grade precision, and our compliance team backs it with full documentation. Aircraft maintenance teams around the world trust it for its proven reliability.

We make it easy to start:

Request a quote today and receive pricing, availability, lead time, and technical datasheets—typically within 24 hours.

Want a sample for evaluation? Just let us know.

Have a technical question? Our team of engineers is standing by.

Serving: OEMs · MROs · Airlines · Distributors

Choose Liyan. Choose confidence in every flight.

Contact: Sales Dept.

Phone: 86-18068808880

Tel: 86-13905198660

Email: jetengineparts@aliyun.com

Add: No. 555, Yangzijiang Road, New District, Zhenjiang City, Jiangsu Province, China

We chat